The GoodVisionGlasses

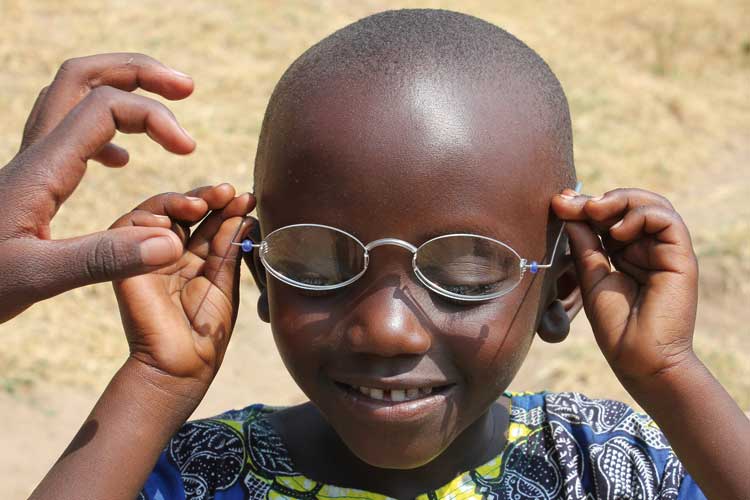

Happy customer with GoodVisionGlasses, Rwanda | © Martin Aufmuth

The idea

More than 950 million people need glasses but cannot afford them (source: WHO).

The resulting loss of income is over $269 billion US dollars per year.

Our goal: The establishment of basic optical care for everyone.

The frame

GoodVisionGlasses are made of flexible spring steel wire. It is very light and at the same time extremely robust – making it ideal for the often harsh environmental conditions in developing countries.

Material cost: about $1.

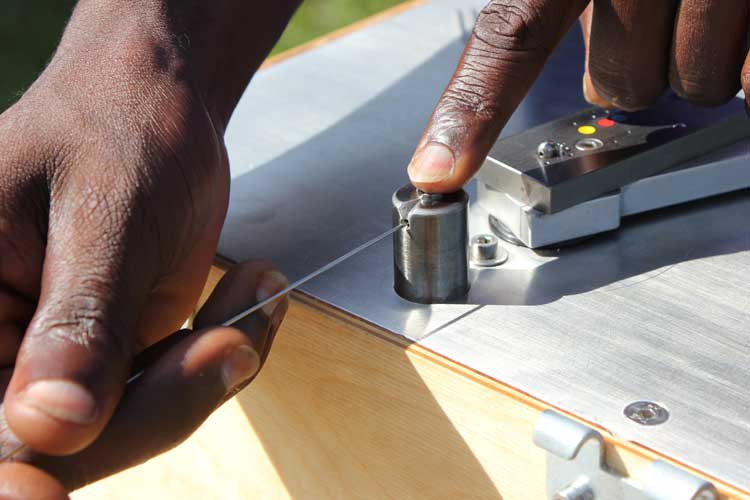

Manufacturing

GoodVisionGlasses are manufactured locally on a simple bending machine which does not require electricity. A truly sustainable approach.

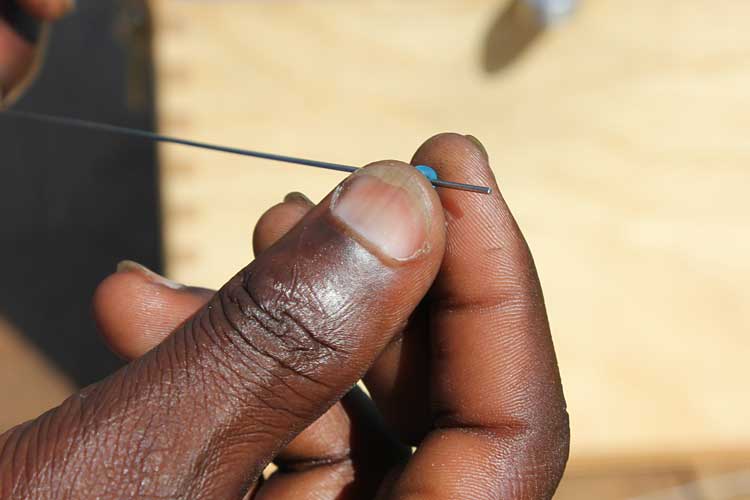

Color markings

Glasses of various sizes can be produced on the bending machine: the yellow marking is for small glasses, red for medium-sized glasses and blue for people with a large interpupillary distance.

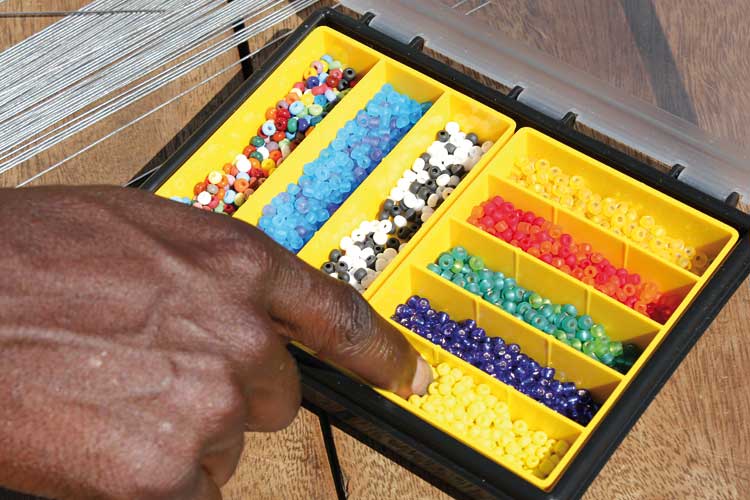

Colorful beads

Different beads are an expression of personality and give the glasses an individual design.

Heat shrink tubing

Colored shrink tube accentuates the temple and nose bridge – heated here over a traditional charcoal fire.

Alignment

Around 30 mistakes can be made when bending a frame.

That is why final frame adjustments are important.

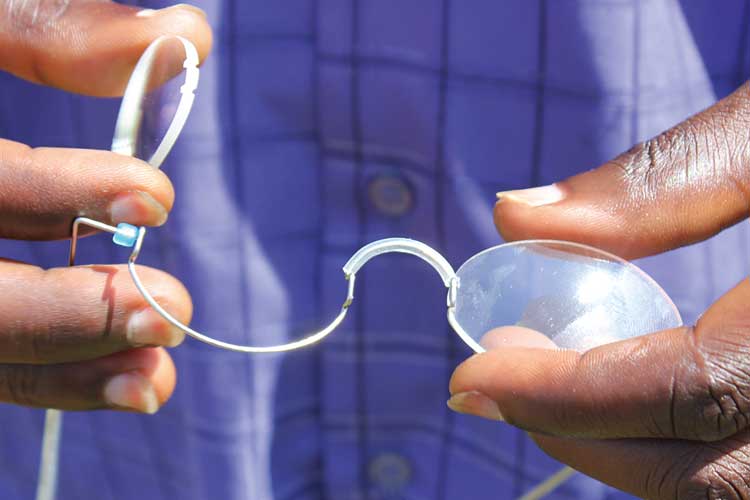

Modular system

The pre-cut plastic lenses are break and scratch resistant.

Lenses come in different powers from -10.0 to +8.0 diopters.

They are pre-cut and can easily be clicked into the frame.

First glasses

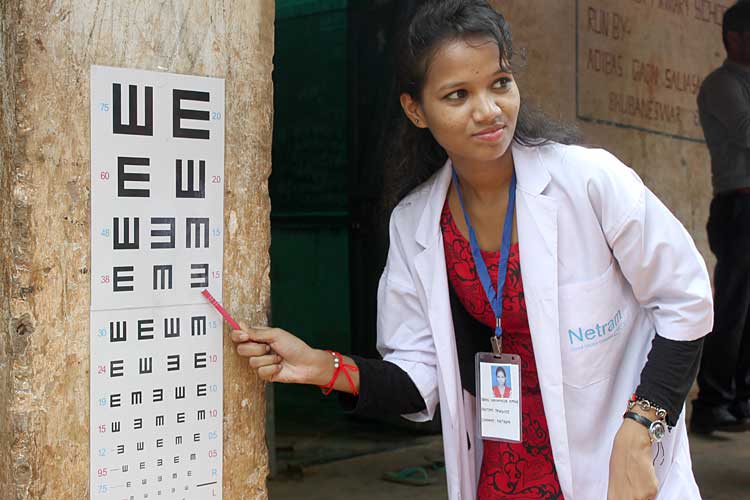

Help on site

Many individuals who live rurally in our project countries lack the resources

to travel to the city for glasses.

That’s why GoodVision teams travel to villages.

People are tested on site and immediately receive their glasses afterwards.

Training

According to a WHO study, more than 65,000 opticians are needed worldwide.

GoodVision trains people on-site in the manufacture of glasses and as ophthalmic specialists.

GoodVision training concept

We developed our own training concept for optical technicians. The “Best Spherical Correction” training is completed in one year. After just a few weeks, the trainees are able to safely carry out a simple eye test and adjust the glasses.

The inventor

Martin Aufmuth invented the GoodVisionGlasses at home in Germany in his basement.

In 2012 he founded the German non-profit organization EinDollarBrille e.V. (OneDollarGlasses), GoodVision’s parent organization.

The Organization

Today over 300 people work voluntarily in Germany, Switzerland and the USA for GoodVision. More than 200 jobs have already been created in the currently ten project countries. EinDollarBrille e.V. Germany finances training costs, bending machines and the project setup from donations. Part of the costs are borne by selling the glasses. Development aid as a social business.

Together with the parent organization OneDollarGlasses Germany, the individual national organizations work under the common umbrella of “GoodVision”. Our goal: to establish basic ophthalmic care for people worldwide.

Share with friends

You might also be interested in

Endurance test

We wanted to know: what do GoodVisionGlasses really withstand?

On the Sunny Island

The GoodVision team supplies the last …

Raidas from the slum

From tea boy to producer of glasses During our...